The quest for green fuel has been the highest priority since the beginning of the 21st century. Its quite evident from the fact that various amendments for environmental protection, promotion of green shipping & introducing the concept of EEDI have surfaced. Shipping industry, which is considered the lifeline for global trading is becoming a threat to the world for its emission of various particles, NOx, SOx etc.

Amid all these deliberations at various global levels of the shipping industry; engineers, naval architects & scientists have come up with advanced technologies to curb the demand and the environmental problems of the industry. One such technological advancement has been the introduction of LNG as a marine propulsion fuel.

Prior to the introduction of LNG fueled vessel market, it was primarily used as 'the boil off' gas on LNG carriers.It was utilized in marine boilers and duel fuel engines. The major purpose of LNG as fuel was to cut out the emissions. Results show that LNG is capable of reducing Carbon-dioxide emissions by 20%, NOx by 85-90%, and nearly a 100% reduction in SOx and particle emissions.

Basically, a marine LNG engine is used as a dual fuel engine that uses natural gas and bunker fuel( Heavy Fuel Oil, Light Diesel Oil) to convert chemical energy to mechanical energy. This is because of the large tank space occupied by the LNG(density is less than air) and limited bunkering options. As a result only a very few small ships that to close to the shore run on complete LNG engine. Figure 1 shows the layout of a LNG propulsion plant.

Cold LNG (liquid gas) is stored in the two insulated flasks (yellow tanks) forward of the engine room. This setup is then connected to the evaporator system which converts the liquid fuel into a low pressure warm gas and is supplied to the gas engine, which turns the propeller through a reduction gear. The engine also supplies the vessel's electrical load by means of a generator driven off the gearbox.

However, the advantages of dual - fuelled engine have proved to be extremely effective, this includes:

Prior to the introduction of LNG fueled vessel market, it was primarily used as 'the boil off' gas on LNG carriers.It was utilized in marine boilers and duel fuel engines. The major purpose of LNG as fuel was to cut out the emissions. Results show that LNG is capable of reducing Carbon-dioxide emissions by 20%, NOx by 85-90%, and nearly a 100% reduction in SOx and particle emissions.

Basically, a marine LNG engine is used as a dual fuel engine that uses natural gas and bunker fuel( Heavy Fuel Oil, Light Diesel Oil) to convert chemical energy to mechanical energy. This is because of the large tank space occupied by the LNG(density is less than air) and limited bunkering options. As a result only a very few small ships that to close to the shore run on complete LNG engine. Figure 1 shows the layout of a LNG propulsion plant.

|

| Fig. 1: LNG Tank, Engine & propeller connections. ( Image Courtesy: DNV ) |

Cold LNG (liquid gas) is stored in the two insulated flasks (yellow tanks) forward of the engine room. This setup is then connected to the evaporator system which converts the liquid fuel into a low pressure warm gas and is supplied to the gas engine, which turns the propeller through a reduction gear. The engine also supplies the vessel's electrical load by means of a generator driven off the gearbox.

However, the advantages of dual - fuelled engine have proved to be extremely effective, this includes:

- Operational flexibility.

- High efficiency.

- Low emissions.

- Operational cost advantages.

At present it may be a marine fuel and replace the heavy fuel oils. There is no problem to prepare the gas turbines and boilers (for steam turbines) for burning natural gas. It affects continuous combustion – this is an advantage for these engines.

By reason of efficiency LNG as a marine fuel in diesel engines can be used as – two and four stroke. The propositions are dual fuel (DF) or three fuel (TF) engines. The engines may work on heavy fuel oils, if necessary on marine diesel oils (during manoeuvres or low loads) and of course on natural gas. In case the two stroke diesel engine works on natural gas it is needed to inject a pilot dose of liquid fuel (more often 1% of marine diesel oil) for the facilitation of self-ignition of the fuel-air mixture. The natural gas is injected to the cylinder under pressure about 25-35 MPa (it is a problem to use high pressure compressors). In the case the four stroke diesel engines the natural gas is passed to the air inlet channel under a pressure of about 0.5-0.6 MPa (more convenient pressure), and a pilot dose of MDO or HFO is needed too. The dual fuel engines are not sensitive to gas quality and the load.

LNG vs HFO

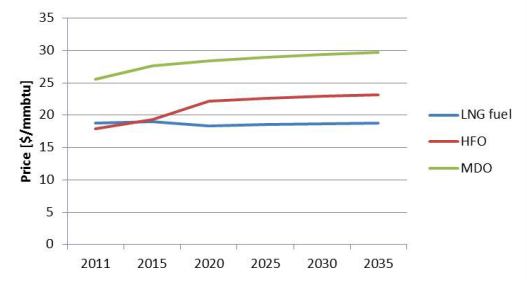

The price of LNG depends on the HFO price, but it is often cheaper. Taken into account the LHV(Lower Heating Value) of fuels and theirs prices, the cost of LNG is about 60% of HFO. On gas carriers the cost of boil-off gas is decreasing due to savings of re-liquefaction process. Natural gas prices (including LNG) has been reduced the last two years due to the introduction of shale gas in the US market. This is a reason that LNG has improved its competitiveness to HFO, especially on ECA (Emission Control Area) where it is needed to clean the exhaust gases.

The cost of LNG storage and the much needed safety equipment increase its cost. On a long stay (due to the shipyard) the fuel tanks must be emptied because of fuel vaporization. On the other hand LNG is a very pure fuel. The operational costs of engines are decreasing. The engines are in the better technical condition and the number of emergency situations and failures is decreasing. This is money too!

However, the methane emission for the LNG pathway is eight times higher compared to the HFO pathway and accounts for 20% of the total GHG emissions for LNG. This contribution is mainly from the combustion of LNG. This means that the performance of the engines plays a major part in the overall performance of LNG as a marine fuel since a small increase in the methane slip will increase the environmental footprint for LNG. As a curiosity it can be seen that if the methane slip from the LNG engine increases with only 12.2%, then HFO will be the most environmental friendly fuel in a life cycle perspective.

In my opinion LNG will be competitive with HFO taking into account only the price during the next 20 years, later it will be still better. Taking into account all the other parameters the LNG competitiveness is better. Figure 2 shows the existing ECA and possible inclusions to the areas in the future.

|

| Fig. 2: ECA Zones around the world. ( Image Courtesy: NORUT) |

If you take a deeper look into how much sulphur & Nitrogen (oxides) reduction the ECA's have achieved, you would definitely be astonished by the level of the stringent goals set to curb SOx & NOx emissions as per the IMO Tier III regulations.

|

| Fig. 3: Sulphur emissions Vs. Years. ( Image Courtesy: Google Images) |

LNG Supply & Pricing

Various estimates of annual consumption of fuel oil for marine fuel are reported. The IEA reports that bunker demand in 2010 was 235 million metric tonnes, comprising approximately 180 million tonnes of residual fuel based products and 55 million tonnes of distillate fuel products. This is equivalent to about 180 million metric tonnes of LNG - nearly 75% of worldwide LNG trade in 2012.

Worldwide LNG demand is projected to grow at more than 5% annually through 2020. Asia – Pacific LNG demand in 2012 represents nearly 70% of global demand and Potential projects that Asia –Pacific demand will continue to pace global demand. Supply must expand rapidly to meet worldwide demand and premium priced Asia Pacific demand in particular.

|

| Fig. 4: Amount of LNG supplied Vs. Years ( Image Courtesy: DNV) |

Pros:

- No need to install further treatment for NOx.

- Potential CO2 reduction ( about 20% every journey).

- Much lower maintenance.

- Cheaper than HFO.

- Spills disappear when in contact with water.

- Meets Tier III & SECA requirements.

- Stored at atmospheric pressure.

- Finally, the most important of all more gas reserves than oil.

- Not much infrastructure development.

- Chances of methane slip.

- Skilled & trained crew required for to operate LNG as fuel.

- Few places to bunker making route scheduling less optimized.

- More space required for gas system on board.

- Safety aspects increase complexity of the supply chain, ship design & operation.

Conclusion

The use of LNG as ship fuel promises a lower emission level and, given the right circumstances, lower fuel costs. So even if there is an increase in the GHG's due to release of methane(very less though) for the sake of reduction of SOx & NOx emissions, the overall results & efficiency is a lot better and greener. Until we find any new or better mode of green propulsion, the use of LNG will definitely help us delay the apocalypse!LSD

Article By: Tanumoy Sinha

Recommended Readings:

Cooper Freer is an independent, trustworthy, customer focused company, specializing in compressed air systems and services. We are dedicated to serve our customers with high quality services.

ReplyDeletevery helpful information thanks Sendhamarai Engineering Boom Lift

ReplyDelete