Environmental issues have always been an integral part of the global shipping industry. Starting with greenhouse gas, ballast water, oil pollution and much more. In fact, it was estimated by International Maritime Organization (IMO) that there might be an increase up to 72% in carbon dioxide emissions from shipping if no actions are taken. Therefore, numerous meetings, conferences and discussions at IMO have resulted in the development of an energy efficiency design index (EEDI) that has the broad and emphatic support of Governments, industry associations and organizations representing civil society interests. The main stakeholders over whom the regulation will have a direct impact over are the shipowners and operators.

What is the EEDI ?

EEDI is an index quantifying the amount of carbon dioxide that a ship emits in relation to the goods transported. The actual EEDI of a vessel is called the "attained EEDI" and is calculated based on guidelines published by IMO. The result must be below the limit ("required EEDI") prescribed in MARPOL.

For existing vessels, the EEDI is in most cases irrelevant. For new ships, a technical file must be created showing the attained EEDI and its calculation process. The EEDI and the technical file will be subject to verification by the flag administration. Note that the EEDI and the Technical file are not required for all types of ship.

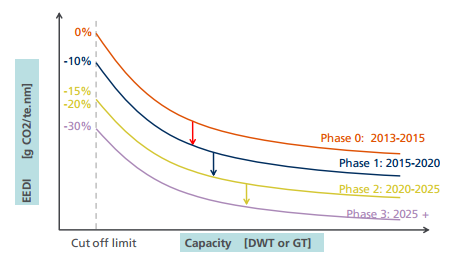

The EEDI for new ships is the most important technical measure and it aims at promoting the use of more energy efficient (less polluting) equipment and engines. The EEDI requires a minimum energy efficiency level per capacity mile for different ship type and size segments. It was implemented since 1 January 2013 for a first two year phase zero when new design meets new reference level for their ship type, the level is to be tightened every five years and so EEDI is expected to stimulate continued innovation.

As long as the required energy efficiency level is attained, ship designers and builders are free to use the most cost efficient solutions for the ship to comply with the regulations.

The CO2 reduction level (grams of CO2 tonne mile) for the first phase is set to 10% and will be tightened every five years. Reduction rates have been established until the period 2025 - 2030 when a 30% reduction is mandated for applicable ship types calculated from a reference line representing the average efficiency of ship built from 2000 and 2010.

The empirical formula of EEDI is as follows:

EEDI = (Power · Specific Consumption · Carbon Conversion) / (Capacity · Speed)

However, EEDI as presently drafted is not applicable for all ships, especially non cargo carriers and also not for all types of propulsion system (eg. ships with diesel-electric, turbine or hybrid propulsion systems will need additional correction factors).

The first iteration of the EEDI has been developed for the largest and most energy intensive segments of the world merchant fleet, thus embracing 72% of emissions from new ships and covering the following ship types: oil and gas tankers, bulk carriers, general cargo ships, refrigerated cargo carriers and container ships.

You might think that why RO-RO is excluded even if they carry cargo but if you carefully analyse the formula given above you would find that the design of fast ships like RO-RO will never present a good index as speed is taken too linearly into consideration here and hence vessels with Diesel electric hybrid system propelled vessels are difficult to be included in the formula.

The EEDI requirements will apply to new ships above 400 gross metric tons only, where "new ship" means a ship:

- for which the building contract is placed on or after 1 January 2013.

- in the absence of building contract, the keel of which is laid or which is at a similar stage of construction on or after 1 January 2013.

- the delivery of which is on or after 1 January 2015.

A ships attained EEDI must be equal to or less than the required EEDI of the ship type and size, which will be a function of the reference line value and a reduction factor X,

Reference lines have been developed by the IMO for a number of ship types. The EEDI reference lines refer to statistically average EEDI curves derived from data of existing ships. The reference lines are ship specific and dependent on ship type and size. Reference line values are calculated using the following table and equation:

SEEMP stands for Ship Energy Efficiency Management Plan. The main purpose of the SEEMP is to lay down a mechanism for the company or ship to improve the energy efficiency of a ship's operation and preferably link it to a broader corporate energy management policy. All ships must have a SEEMP on board before the issuance of the first IEEC (International Energy Efficiency Certificate).

The SEEMP will initiate monitoring and target setting and look at concrete measures to be implemented for each vessel.

List of parameters that effect the EEDI

The following are provided as a list of typical parameters which may have an effect on ship's EEDI. Note: This is not an exhaustive list.

- Ship type and design for ice

- Type of fuel

- Size and Specific fuel consumption of main engines( or main propulsion motors)

- Specific fuel consumption of Auxiliary (power generation) engines

- Hull Form

- Hull appendices

- propeller

- Electric power requirement for non-propulsion systems

- Capacity at Summer load line

- Draft and trim at Summer load line

- Energy saving devices as specified in EEDI Technical file

Conclusion

Following adoption in 2011 and entry into force in 2013, the EEDI will aim at reduction of about 45 to 50 million tonnes of CO2 emissions from all new ships by 2020. For 2030 the reduction will be between 180 - 240 million tonnes annually.

There is therefore, every confidence, among the vast majority of the international maritime community, that the EEDI will result in more efficient ships, in reduced emissions of GHG's, in Environmental effectiveness and in a significant contribution by a global industry to the global efforts to stem climate change. LSD

Article By: Tanumoy Sinha

Great post!!thanks for sharing!!

ReplyDeletenebosh course in chennai

nebosh courses in chennai

nebosh course in chennai

nebosh courses in chennai

nebosh in chennai

Diploma in fire and safety courses in chennai

safety course in Chennai

iosh managing safely course in chennai

If you've got an eCommerce blog and utilize Shopify then you are going to know that Shopify enables you to optimise your store for Google SEO. Click here for more interesting information on Terms Of Use - Niche Tyrant.

ReplyDelete